The David Hamel's Pictures Album

Courtesy of Tracy from the Hamel's Teamwork

created on September 23th, 1999 - JLN Labs - Last update October 1st, 1999

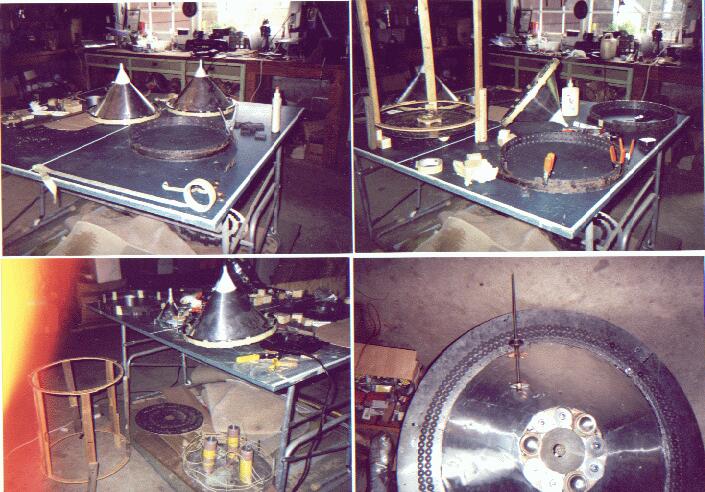

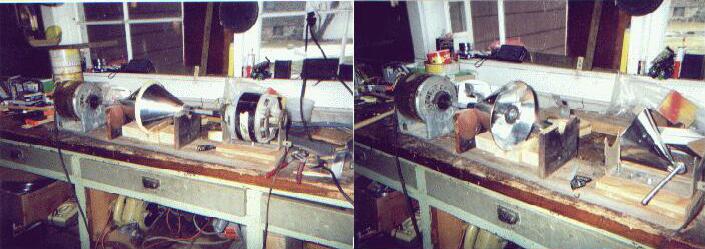

The Hamel's devices build Tracy Jones

The Drum, the Hinthorn device and the HFS wing build by Tracy.

The Plexiglass models (below)

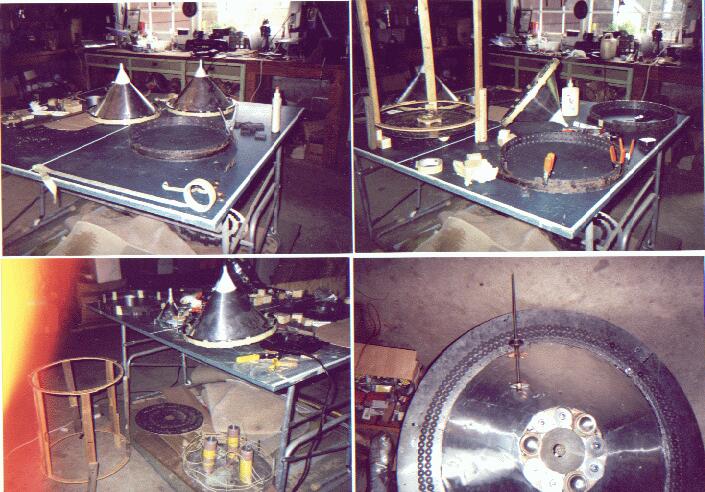

" I had figured out how to solve the problem of the droopy wings by paying a very nice guy in a plastic shop to form me 4 domes with the horizontal wings at only a cost of 215.00 per. He later did my inner cones for another 30.00 per. The only advantage of doing this was not only did I not have any more problems with the wings, but you could see what was going on inside which was pretty much nada. It's kind of fun trying to get smoke to go downward into the inner cones after you have forced it up to the top to see how the air is suppose to flow using a lighted cigarette and blowing the smoke between the wings. Of course I was fortunate to find a hacker to do this for me. " Tracy.

" The bottom right shows my cup for my diamond shape pinions scaled down to fit the domes. I was very fortunate in that my friendly Canadian machine shop foreman only charged me 465 dollars for all nine pinions in US currency. I couldn't find an American machine shop to do the work even if it was done in aluminum. I used my cue balls for the shoulder pinions. " Tracy.

" The bottom right was the cover I used for the top. I finished the device only to find some more nada. During this period of time I had the good fortune to meet Dan Dial. I had decided to spend the winter in San Diego bugging Dan LaRochelle for any information he might have on the subject and try my hand at using the Enhancer to help people help themselves. This was done with high expectations of huge donations from those getting better all the time. However, most of my prospective clients didn't have any money, but they used the machines anyway and I was able to sell a few I put together myself from kits I purchased from Dan. I along with Bob Thomas left our machines at his place for him to study and maybe get the damn things to work. I returned the following summer with great expectations on making yet a third hfs after working with David in Ontario. Dan decided it was too much out of kilter to do anything with and he also informed me that plastic wouldn't work anyway. Dan now has the plastic domes and I have some of the magnets in my third hfs. This one you already have seen some of the photos of which I have about 150 to date. Don't worry, I won't be sending you these enmasse, but will accommodate anyone on an individual basis. " Tracy.

" The top photo shows the fan motor that finally burned up that I used to turn the floating magnet. The bottom shows the wiper motor in action. None of the photos showed any sparking. However, the largest sparks came at the bottom of the shaft at the motor where it was attached and the arm just before it turns down at a ninety degree turn. These two joints are loose so the arm could move when the motor rotated. " Tracy.

" The top photo shows the wiper motor being hooked up. The bottom photo shows another night shot and the arm extended to the bottom wing which was also loosely attached and showed sparks, but not in the photo. " Tracy.

Other Experiments ( below )

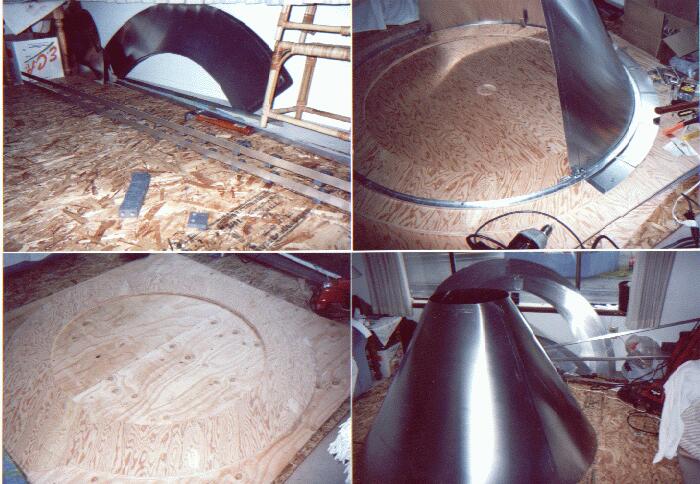

" This

is the last photo of the series. The top photo shows an

experiment that I made using the large aluminum cone hung by a

string from the ceiling. There are as many magnets as you see on

the table on the bottom inside of the cone. I watch this cone

oscillate for a total of 45 minutes one day, just going back and

forth.

The setup in the bottom two photos is an attempt to spin two

magnets in rejection in opposite directions enclosed in the cones

at high speed. The best I did here was burn up one of the ac

motors. The TV never blinked once. " Tracy.

Test reports

Sujet :

hfs report 9/22/99

Date : 23/09/99 03:28:13

From: tracy@plix.com (Tracy)

Good evening everyone,

This afternoon, I designed a bracket to hold my old time Buick

windshield wiper motor I purchased and attached a 1/2 inch strip

of aluminum to serve as the arm. This I attached to the bottom

wing and began to oscillate the wing using my battery charger as

a power source. The bottom wing oscillates about 1/4 inch and the

top wing slightly less. The center floating magnet oscillates

about 1/8 to 1/4 inch, and does not spin. Da fatlady was witness

to this and I asked her to go home, a short distance away, and

give me a phone check. I have a power transformer located

approximately 60 feet from the device and it's estimated to be

about 20 to 25 feet above the ground. The phone lines run from

this pole to the house and the closest distance to the hfs is

approximately 30 feet. Most of the phone interference was towards

the direction of these lines and pole. My portable phone was

disconnected 6 times with the furthest being about 5 feet and

lying in a line towards the pole transformer. This line of sight

and closer to the hfs also produced the loudest noise

interference and when the noise increased, it continued to do so

until the phone disconnected. The only other area of interference

noted was below the device towards the edge between the phone

lines and the hfs, above the edge of the wing itself which is

where the magnets are and the opposite side of the hfs from a

direct line towards the power pole. I then hooked up my TV along

side the hfs on a level just above the wings and about 4 feet

distance. Without my cable hookup, I can only receive one station

and the reception is very poor, but the sound is fine. I noticed

considerable interference with the tv, but not the sound. The

strongest build up before the phone had disconnected was when I

oscillated the top wing by hand while the bottom wing was being

oscillated by the motor. When I turned the motor off, all the

interference on the phone ceased. The windshield motor has been

running for 75 minutes and I intend to leave it running all

night.

Far as I can determine, it will continue to operate barring any

breakdown in the attached arm. The last disconnect was when I had

the phone close to the skin of the hfs and between the horizontal

portion of the wing and floating magnet. The distance at its

strongest detected interference was when the phone was within 2

inches of the skin and it was like this completely encircling the

hfs. This is most interesting because it makes no difference

concerning the location of the overhead phone wires or the pole

transformer. It remains a constant all the way around the hfs. If

it is still here by morning and the motor is still operating,

then I will devise another design to hooked up the arm to the top

wing and try that. I've also taken 5 photos of the arrangement.

Will keep you posted. Tracy.

____________

Sujet : report 2 hfs

9/22/99 @ 95 minutes

Date : 23/09/99 03:42:28

From: tracy@plix.com (Tracy)

An interesting development just began. While still oscillating as before with only the motor, the TV is now resonating with the movement of the wings with both the sound and picture turning itself off and on. I've asked DA fatlady to come over and witness this development. Tracy.

____________

Sujet : report hfs

9/22/99 @ 215 minutes

Date : 23/09/99 06:17:23

From: tracy@plix.com (Tracy)

The windshield wiper motor is still working and ever time its arms to the wing touch or move within the connected joints it sparks and sometimes very much. This also happens when aluminum touches each other. It does not have to be steel. The TV appears to just about had it with only large flashes showing every time it sparks. No program at all now. I was speaking to Louis on the portable phone earlier and it disconnected on him also when I placed it close to the wings. I've taken two more pictures with flash. It's now 9:02PM PST and will remain up for a while longer. I will also leave the motor running. Tracy.

____________

Sujet : report hfs

9/22/99 325 minutes

Date : 23/09/99 07:48:16é)

From: tracy@plix.com (Tracy)

The tests began at 4:50PM and it's now 10:15PM, that's 5 hours and 25 minutes or 325 minutes and the damn thing is still looking like that pink bunny rabbit with the ever ready battery attached to it, It just keeps running and running, but no lift off. I did make another test thinking that it must be grounded somehow to be sparking like it is. I detached the motor from the top of the structure where I have it bolted and isolated it from the hfs while it was still running. The sparking continued when ever the aluminum arm touched the frame as it leads to the bottom wing or when the arm moved while loosely attached to the bottom wing. I rebolted it and then ran an alligator clip from the bottom wing and struck the top wing. No spark. When I struck the clip to the frame from the top wing, still no spark. I then attached the clip to the frame on the opposite side and struck the bottom wing, lots of spark, but none from the top wing when I struck it. Each time it sparks no matter where the spark comes from, the TV goes bonkers with lots of large flashing from the screen. This flashing is so intense,it's like looking down into the tube itself and seeing the rear end of the tube. Getting sleepy so will retire and check on it later. It's still running now. Tracy.

____________

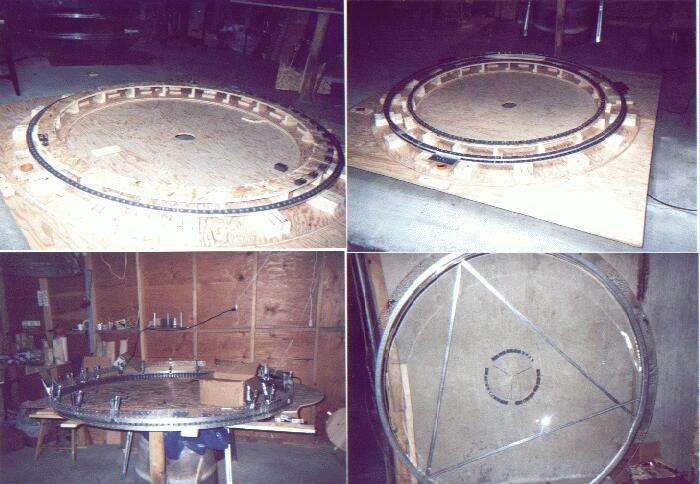

Sujet :

PartslistTracyswheels

Date : 30/09/99 09:27:39

From: tracy@plix.com (Tracy)

My shopping spree in

Seattle netted me enough material to begin my "Tracy's

wheels" within the next couple of days. Tomorrow I will pick

up from the machine shop my wheels and assembly will begin ASAP.

In the meantime I will give you a list of material I will be

working with that I purchased in Seattle. This does not include a

complete list because I will be using material left over from my

previous assembly and that which I will take off the current one.

The purpose of sharing this information with you is to let you

know what I will be using and at what cost so you can compare

your costs in the event it works and you wish to assemble one

yourself. I repeat, this is a modification of the HFS and is my

own interpretation of how it might work. When I begin assembly, I

will make a report of what I've done and how I did it and I will

try to do this on a daily basis. I usually make my health report

in the early morning hours and will do this report at the same

time. I will also be taking photos as I proceed and will try to

make drawings when ever possible. Currently, my brother is making

a drawing from a sketch I left him while I was in Seattle. Soon

as it is presentable, I will forward it to you. I trust that if

you will compare it to the HFS, you will understand it better.

The object is to provide more surface area for what I consider

the cones to be a capacitor without making it bigger and at the

same time easier to assemble. I've done away with the outer rings

and replaced them with a simple method of centering the rings

(wheels) so the magnets remain in balance, but at the same time

move across one another. I've also designed it so the outer skin

is insulated from the machine itself and provides a means of air

flow that will be vortex if in fact that is what is required. The

center floating magnet is replaced with two fixed magnets in the

center of the hub in rejection to each other. I will be using

soda pop cans for my cups filled with concrete and miniature

snooker balls (hard plastic of 1 and ½ inch in size) for the

pinions. I can also utilize the floating magnet I have now at the

top and have considered the magnetic motor Dan La has introduced

to keep it spinning. Rather or not this is necessary is yet to be

seen. I have also designed a simple method to keep the entire

device moving so that the two middle wheels will be in constant

movement until the device energizes itself if that's what it will

do. If at any time when I am presenting this information to you

and you don't understand the procedure or have a suggestion for

what you consider an easier method, then by all means speak up

and I will either explain why it can't be incorporated or will

incorporate it at that time. The following is a list of material

I purchased for this assembly with a brief reason for its use in

the machine. Most of the material was purchased at the Boeing

Surplus facility in Kent, Washington. Keep in mind concerning the

quantity purchased is because of the purchasing rules as follows:

1) What you see is what you get and no refunds. 2) If you can

find another customer to share your purchase, then you don't have

to buy the entire selection (piece) on display. 3) All purchases

are paid for by check or in cash. 4) Pickup is usually made at

time of purchase. 5) All material is new and is leftovers or

obsolete from previous jobs. 6) Tools, equipment, and furniture

are usually all used. 7) Most material is sold by the pound as

well as some tools (pliers, specialized bits, etc.).

Material Description Use Cost

1. 2 - 4 x 12 ft. .010 aluminum sheets. Capacitors and inner

cones 22.00

2. 1 - 5 x 12 ft. .032 aluminum sheet. Capacitors and skin 56.00

3. 80 feet x 3 feet wide thin rubber Possible insulator 20.00

4. 2' x 8' x 1" acrylic plastic Framing and spacers 50.00

5. 3 - 2" x 2" x 8' solid nylon possible framing

alternative 13.00

6. 2 - ¼" x 24" x 16" aluminum plate hub rings.

44.80

7. 12' x ¼ " rubber mat possible insulator 30.00

8. 28" x 28" x 1/8" copper plate and remnants

general use 16.50

9. 2 large pieces of plywood w/1/16"alum coating possible

structure 10.00

10. 4 - 20' x ½ " rubber belt insulator for skin 4.00

11. 4' x 8' x 1" honeycomb aluminum sheet possible capacitor

16.50

Other items of small import such as 1" shrink tubing at .10

cents a foot to put magnets in to hold in place for other

experiments, 500 plastic ties of different sizes, 7.10, 10 drill

bits .40 cents total, two small wire cutters 1.00, etc.

Tacoma Screw Products:

1. 500 aluminum 1/8 x ½ rivets 12.30

2. 500 aluminum 1/8 x 3/8 rivets 11.48

3. 400 aluminum 1/8 x ¼ rivets 7.10

4. 10 1/8 drill extra hard drill bits 14.00

5. 100 6-32 brass machine nuts 3.15

6. 100 1" 18-8 # 8 screws phil head 11.49

American Games:

12 miniature snooker balls (1 x ½ inch) 24.00

See Also:

![]() Mail to

tracy@plix.com (Tracy) or to JNaudin509@aol.com

Mail to

tracy@plix.com (Tracy) or to JNaudin509@aol.com

Return to Hamel Technologies home page